AguaPods is a division of Dagua. All our Pods are shipped in 20 or 40 foot containers customized to the client’s needs.

With over twenty years of experience in the field, Dagua’s technological success reflects its commitment to developing practical solutions for purifying water. A privately-held company, Dagua is led by a team of leaders in engineering, and corporate management. The company’s technical partners include university research chairs, accredited laboratories, and engineering firms. Now represented in over 25 countries, Dagua through their partnerships with clients have best facilitated the deployment, commissioning, operation and maintenance of its systems and plants.

Distinctive Economic Levers

- Substantial annual savings on chemicals

- Automated stand-alone operations requiring minimal operator intervention

- No complex sludge or toxic waste management

- Very high processing efficiency (minimal backwash water disposal)

- No premature membrane wear from intense or repeated chemical cleanings

- Reduction in the amount of labour required to operate the plant

- Smaller footprint than conventional coagulation processes

- Significant reduction in the need for chlorine, as disinfection is complete

- No alteration in the pH of treated water and thus no remineralisation required

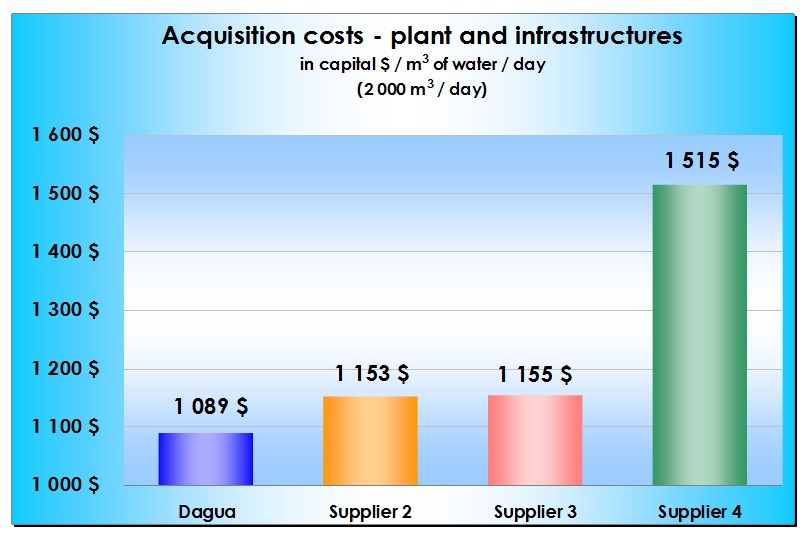

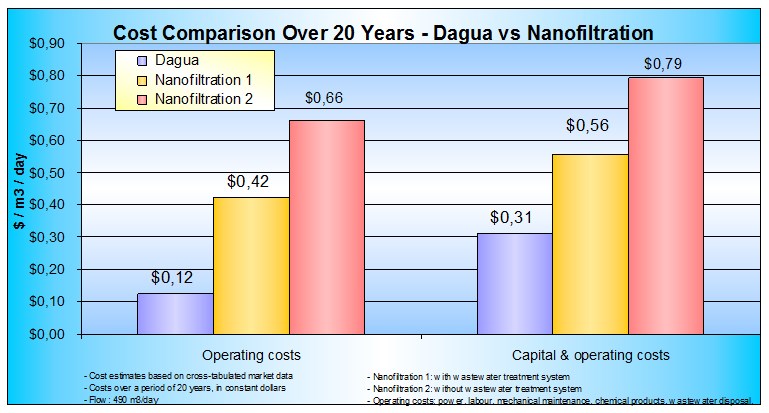

Significant savings in combined operating and capital costs

The following table compares unit costs for DaguaFlo-UMF technology with those generally associated with membrane filtration and nanofiltration in two types of installations. In terms of both operating costs alone and combined operating and capital costs, the Dagua solution is by far the most cost-effective choice.

All told, the technological breakthrough that Dagua has accomplished in chemical-free water treatment enables community decision makers to balance their financial capacities with both regulatory requirements for drinking water and the growing support for sustainable development.

years of experience

AguaPods are Highly efficient, automated and safe

Using the DaguaFlo solution not only streamlines plant operations by eliminating the need for chemical products and sludge management, but continuously monitors drinking water quality and plant operations as well. Regardless of variations in the quality of your raw water, you can always count on a reliable supply of high-quality drinking water, with only 60 minutes of operator attention per day.

For additional ease of operation, a telemetric link (modem or Internet) enables you to monitor and manage plant operations from a remote location. As well, the plant makes process adjustments in response to fluctuations in raw water quality and performs regular system cleanings automatically.